Demonstration of improved Dutch storage, sorting and packaging technologies

Background

Most commonly used onion storages are either farm-based (in shed, home or on field) or a market-based fan-ventilated room, without temperature, CO2 and humidity control. Sorting and packaging is done manually. The traditional farm-based storages and lack of knowledge on quality storage and proper handling of onions lead to avoidable losses of volume and quality during storage. As a result, the shelf-life of the onions is limited resulting in shortages especially from September- December.

What do we do?

Improved storage, sorting and packaging technologies and increased knowledge are needed that contribute to reduced post-harvest losses, extended onion shelf-life and reduced Bangladeshi onion imports. The following activities are therefore implemented during the project period:

- Based on the financial and economic feasibility of the expected storage performance, the following local business partners were selected where the improved technologies are demonstrated:

- Designs are made for a 1) box storage facility and 2) a bag-based storage facility.

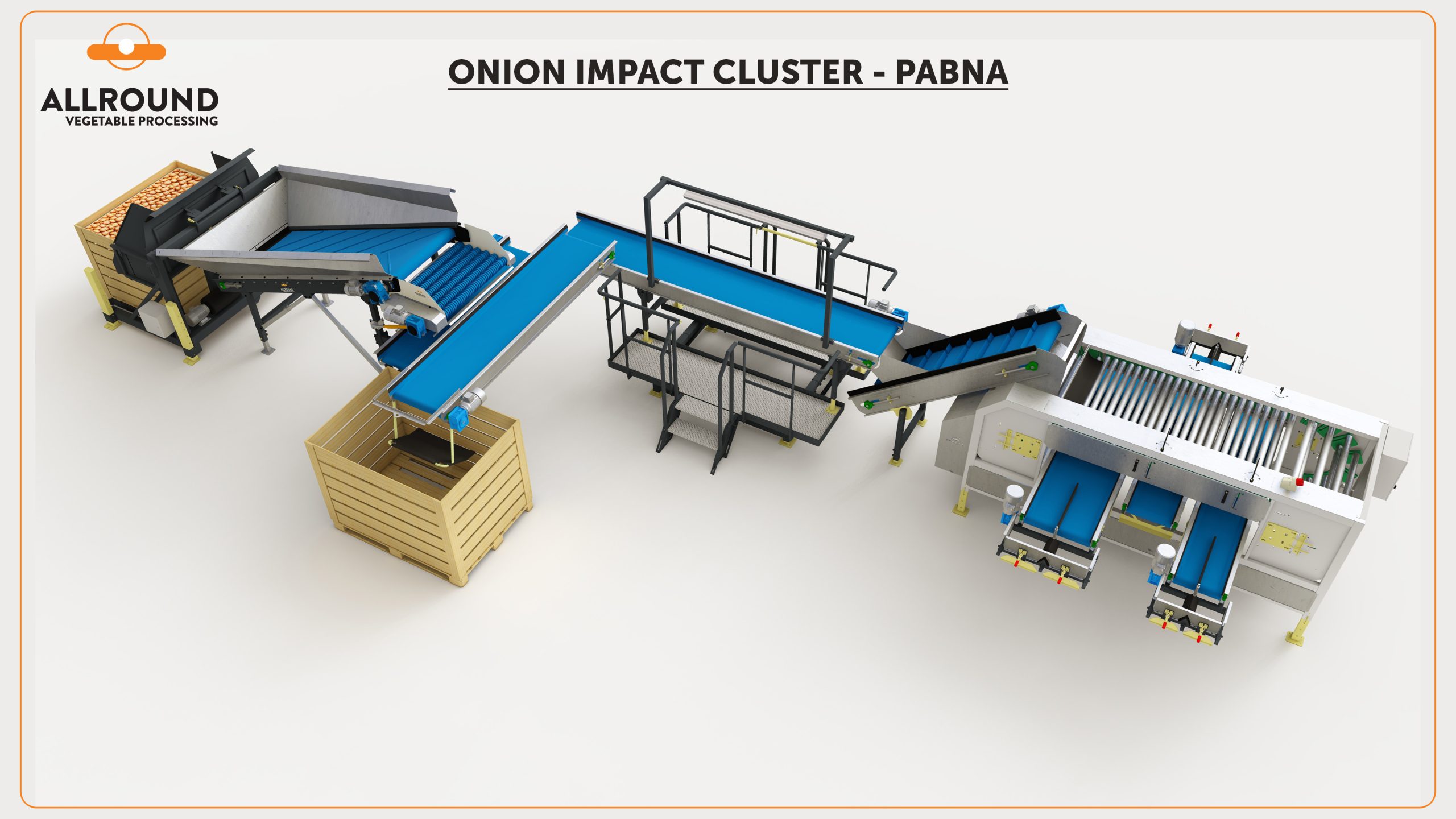

- The storage and handling equipment is constructed, shipped to Bangladesh together with 170 boxes and demonstrated at the storage facilities.

- The storage conditions are monitored using sensors and by coaching the storage managers.

- The operational performance of the selected storage facilities is monitored and reported on.

The activities are implemented by Allround and Waterman Onions and with local support from Deltadesh.

Downloads

Address

Deltadesh (Pvt.) Ltd.

Apt. C-1, House 1/A, Road 79, Gulshan-2, Dhaka-1212, Bangladesh

project @ dutchbanglaonionsupport.com

+ 880 1632 845385